The Orchard Supply Hardware store in Mountain View, which is owned by Lowe’s, is taking a baby step toward a future where instead of just selling products, they’ll be able to help customers build their own.

Imagine going into a store with a broken knob from an antique cabinet and walking out with a brand-new identical item, even though the company that made that knob might have gone out of business a century ago. Or perhaps you fancy a customized lightswitch plate with your family crest or company logo, or a personalized case for your smartphone.

The Mountain View OSH is the first to offer 3D scanning and printing as a retail service. Right next to the Minute Key kiosk — which, for $2, scanned and duplicated my house key — is an area where customers, with the help of a staff member, can scan items they bring into the store and have them “printed” as physical objects.

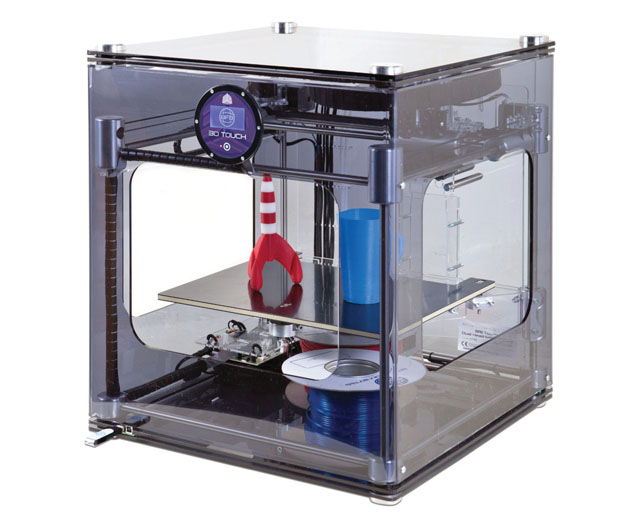

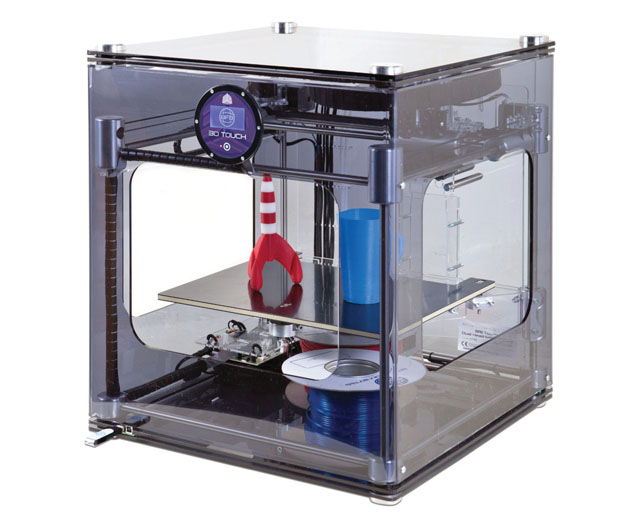

If you bring in an item to scan, it’s a multistep process that sometimes involves having to edit images either on your own or with the help of one of the company’s design consultants. The first step is to place the original object on the turntable at the base of the scanner and wait at least five minutes for the device to create and render a 3D image.

A file is created that, at least for some objects, will probably need a bit of editing to remove any imperfections. 3D scanning is still an emerging technology — don’t expect perfection. In addition to removing any problem areas through the editing process, you can also add custom designs such as your initials or a company logo or you could modify the shape of the object.

Then the file will be routed to a 3D printer, either at Orchard or one of the many service bureaus such as Shapeways.In addition to letting you copy and customize items, OSH is also allowing users to select from vast catalogs of existing designs. iPhone owners, for example, can choose from 3D models for phone cases that people have designed and uploaded to sharing sites, and they can modify those designs, perhaps adding their initials for a monogrammed case. There are thousands of such designs available on the Internet, plus OSH has its own library of doorknobs, outlet covers, address plates and other common items that customers can re-size, decorate or otherwise enhance.

The cost is based on what services you want. For now, it’s free to have an item scanned and have them provide you with a file that you can customize yourself (there are plenty of available programs — some free — that you can use to design or modify 3D printing images) or you can pay as little as $10 to have one of their design consultants work with you. The designer, who is remote to the store, will work with customers while they’re in the store or, later, when the customer is working from their home PC. The cost of printing depends on the size, complexity and materials.

The Mountain View store’s 3D printer can handle simple plastic items in black, white and blue, but if you want to print in another color or a material other than plastic, they can send the file to a remote service bureau that will build it and ship in back to you. There are a variety of available materials including ceramics, various types of plastics, bronze, brass, stainless steel, and for the well-heeled DIYer, titanium, gold and silver.

I laughed when I first heard about printing something in an expensive metal till I realized that these printers can be used to produce jewelry. I could imagine printing out a ring in plastic to see how it looks and feels and then creating your own customized gold or silver ring.

The service is a project of Lowe’s Innovation Lab, which is based at the NASA Research Park in Mountain View. Kyle Nel, the executive director of Lowe’s Innovation Labs, said in an interview that the project “is part of a broader functionality vision to be able to help people get the things they want whether it’s a ell phone case or, more likely, home improvement products.”

Nel said that the technology would eventually enable stores to offer a vast array of products.

“There are a lot of things that we wish we could carry but we just can’t. It’s impossible to stock every single thing all the time. So this already fills a very big need to get people what they need right then.”

For now, the technology is fairly limited, but I see a promising future in store-based 3D scanning and printing as machines become more sophisticated and able to not just stamp out simple products but also assemble more complex objects. Someday, instead of having to roam around a big-box retailer for a part or even a full product, customers could design their own or select one online and pick it up at a nearby kiosk.